Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapter

3 – P ressure Transient Analysis (PTA)- p79/743

)

ln(

t

and

d

dp

t

d

t

dp

z

u

u

) (

ln

)

ln(

) (

ln ) (

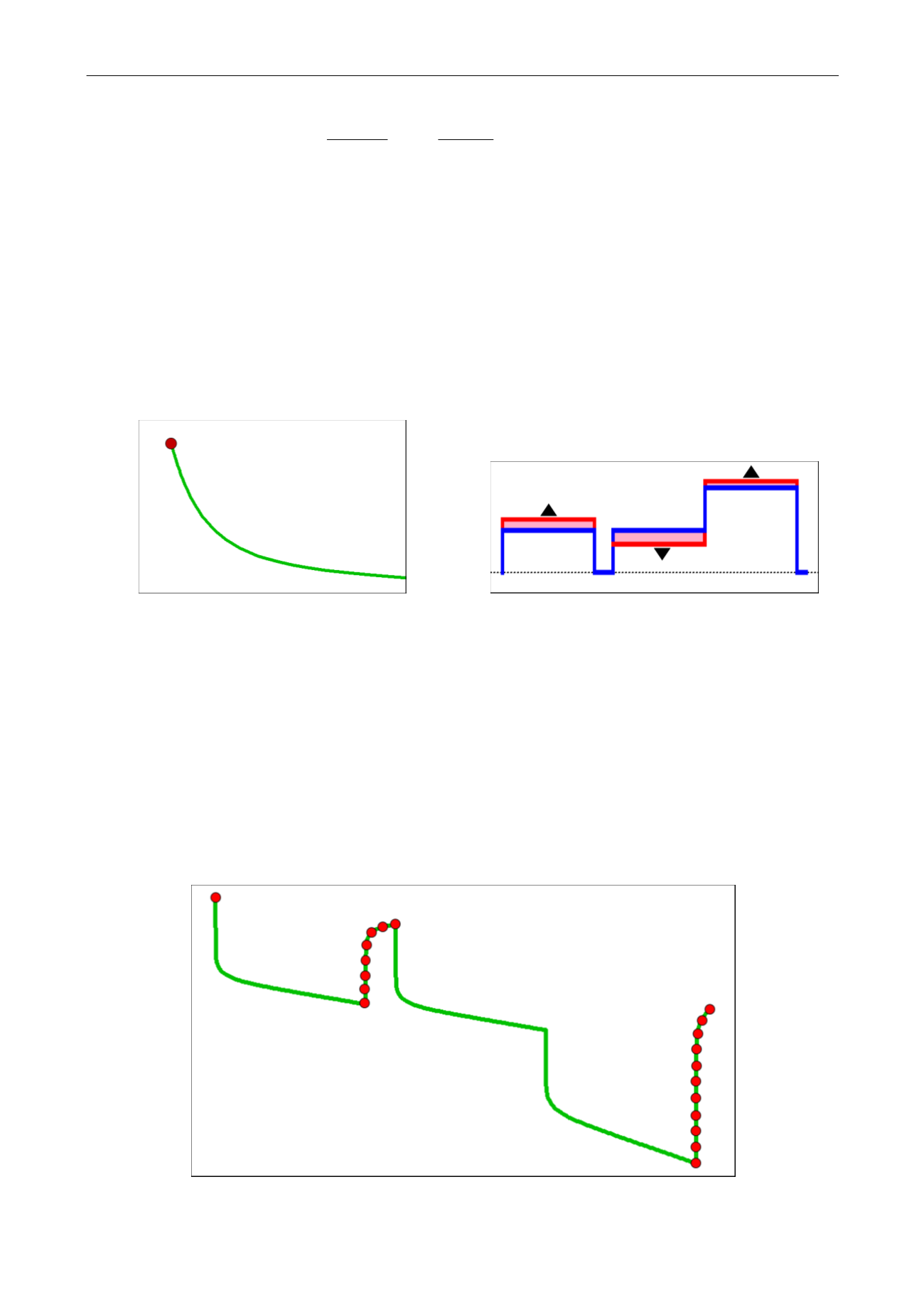

The principle of the new deconvolution method is to find the derivative curve z(

) which, using

a modified convolution expression, will match the data. The curve z(

) is defined as a polyline

or a spline. It has an initial point, as (0,0) makes no sense on a loglog scale. Its time range is

the elapsed time between the beginning of the production history and the last data point we

will try to match (3,200 hr in the previous example).

The curve z(

) is the main unknown. There are two additional sets of optional unknowns: the

first is the initial pressure p

i

, which may or may not be known. The last unknown is a tolerance

to errors in the rate history, which we need to introduce for the optimization process to

converge.

Fig. 3.D.6 – 2

nd

unknown: p

i

Fig. 3.D.7 – 3

rd

unknown:

q’s

3.D.2.b

Problem objective function

The three unknowns above are adjusted, in a nonlinear regression process, to minimize an

objective function. This objective function has three components.

Naturally, the first and main component of the objective function we want to minimize is the

standard deviation between the convolved model and the pressure data

(Fig. 3.D.8below).

This may be all pressure data or, more likely, a series of time intervals where the pressure

data is considered reliable. Typically, successive build-ups are a good candidate, unless the

producing pressures are exceptionally smooth as in the case of clean gas tests for example.

Fig. 3.D.8 – 1st objective function

minimize distance between simulated and real data