Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapter

3 – P ressure Transient Analysis (PTA)- p95/743

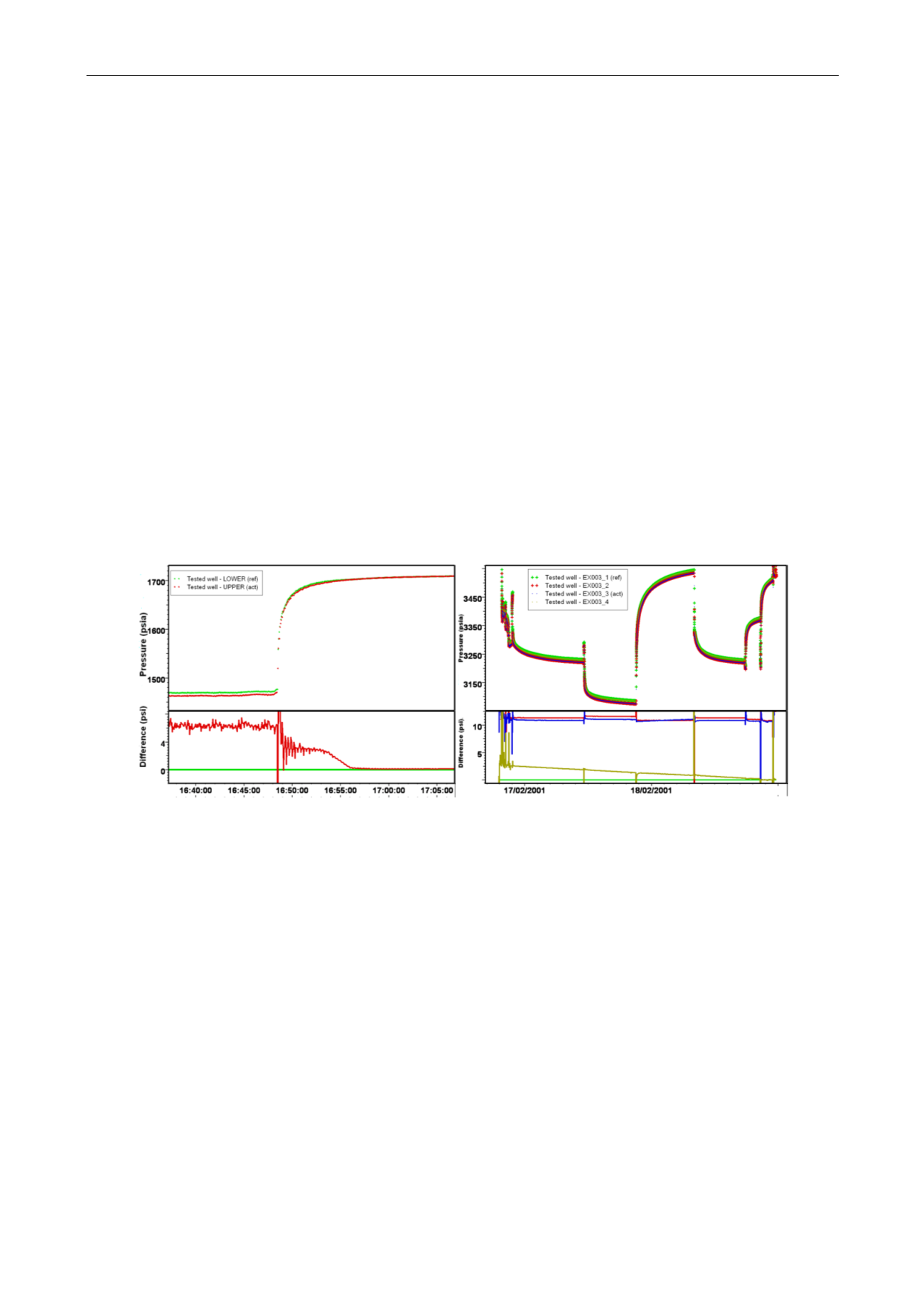

Quality Control has fortunately become a growing concern. Previously, an interpretation

engineer would often consider the buildup data only and match it with, for example, a radial

composite model; whilst all too readily ignoring the possibility that the test behavior could

indeed be related to wellbore phase redistribution. An efficient tool to diagnose wellbore effects

is the dynamic calculation of the difference between the gauges measuring the same data. The

value of the difference itself is of little interest as long as it stays within the gauges accuracy.

However, variations of the difference may be a valuable source of information.

When two pressure sensors are set at the same depth, as with a dual gauge carrier, their

difference can be used to check their synchronization (time shift) and their coherence. Gauge

failure and gauge drift may be identified.

When the gauges are set at different levels, as in a tandem configuration, any change of the

pressure gradient occurring between the gauges may be detected. In the presence of phase

segregation problems, the proper placement of dual gauges may help qualifying and even

quantifying these problems. The engineer will avoid pointlessly interpreting and using a

complex reservoir model behavior that has absolutely nothing to do with the reservoir.

In the absence of dual gauges, one can calculate the derivative of the gauge versus time, and

plot it on a linear or log-log scale. This will act as a ‘magnifying glass’ of the pressure behavior.

Fig. 3.E.6 – Data Quality control using dual gauges and Drifting gauge

Even though people associate the difficulty of well test interpretation to the modelling part, a

lot of thinking takes place at this stage of the interpretation, as it defines the starting point

from which the diagnostic will take place. Failing to identify any operational problems can

potentially jeopardize the whole interpretation process.

There is a side advantage in performing a comprehensive Quality Control: after going back and

forth between the data and the well test report, the interpretation engineer will know what

happened during the test, even if he/she was not on-site.

3.E.4

Editing data

Loaded data may be the result of careful post-processing by the data acquisition company, in

which case no or little editing may be needed. But very often the interpretation engineer will

have to gather data of unequal quality and from different sources. Pressures will often be

acquired downhole in real time or with a memory gauge, while rates will still be measured at

surface and come from the well test report with a different time sampling.