Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapter

3 – P ressure Transient Analysis (PTA)- p94/743

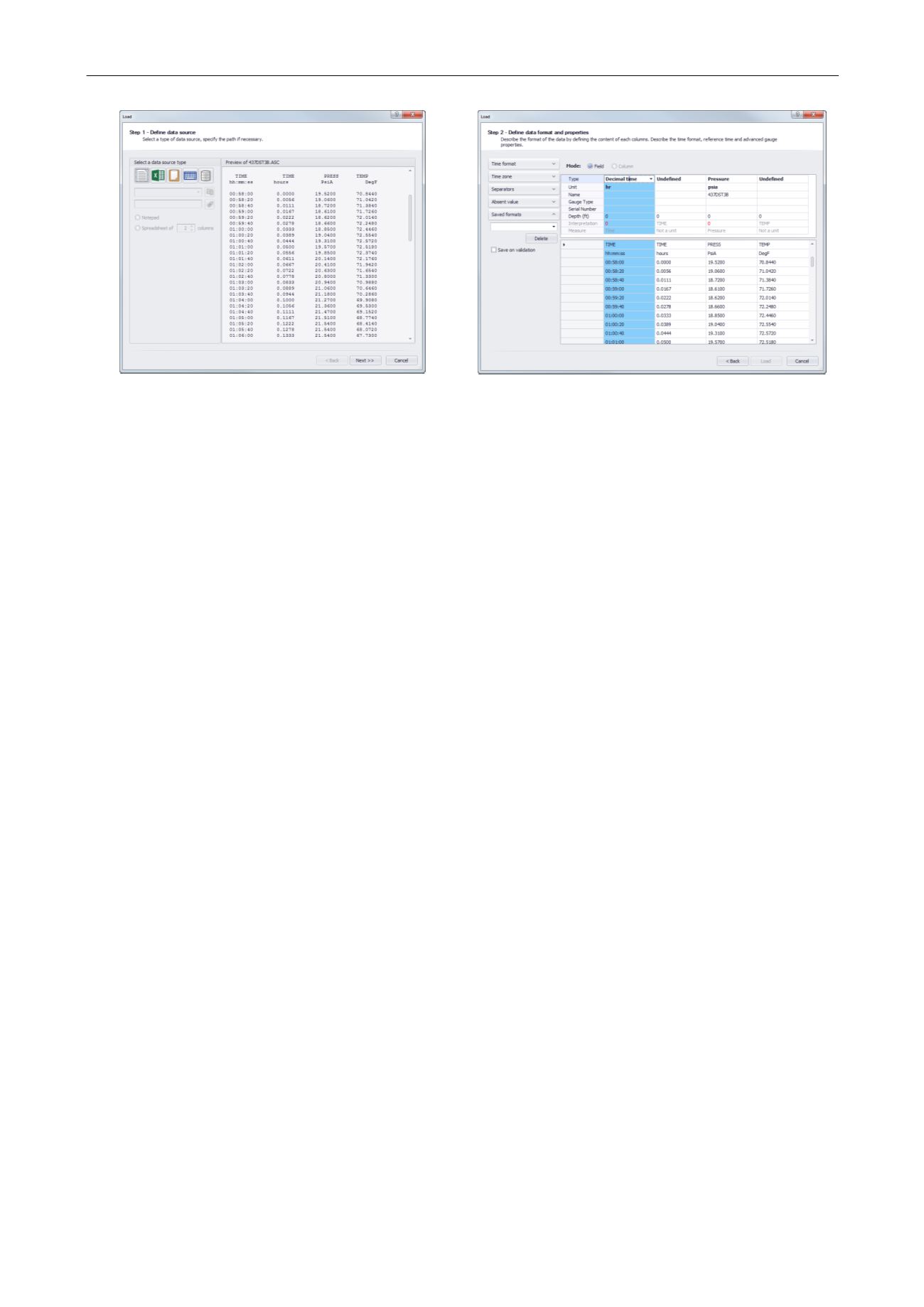

Fig. 3.E.4 – Loading Data: Define data source Fig. 3.E.5 – Loading Data: Define data format

Unlike for open-hole logs and despite several attempts in the past, as of today (2010) no

industry-standard ASCII format has emerged to execute the load with a click. In Canada the

EUB has published a format (PAS) for compulsory electronic submission of test data and

results, but this remains very oriented towards local legal procedures. So software packages

have to provide the engineer with the flexibility to interactively define the file format, in order

to cover the wide variety of existing files.

Originally, the amount of data was a real issue because of limited available memory running

under DOS, the cost of computer memory, and the fact that the size of the data arrays had to

be declared and set by the software programmers at compilation time. All these limitations

have gone. Today’s software can easily handle multiple gauges and volume of gauge data

acquired during a well test which is sometimes more than a million data points.

The recommended procedure is to load all data acquired from all gauges during the well test,

and not just a filtered subset. Filtering can always been applied later, on duplicate data sets.

However, things are changing with the spread of permanent downhole gauges and the

increased usage of production data in Pressure Transient and Rate Transient Analysis. The

amount of production data is one order of magnitude higher, and is much less smooth than a

typical buildup. Smart filters, such as wavelets, are increasingly required to reduce the volume

of the data, retaining any trends and significant changes and at the same time eliminate noise.

The processing of Permanent Downhole Gauge (PDG) data is covered in another chapter.

3.E.3

Quality Control

Quality Control is an essential part of the interpretation, too often overlooked in the past, it

includes:

Validation of the gauges: identification of failures, drift, clock failure, resolution, etc.

Identification of operational problems.

When applicable, identification and correction of tidal effects.

Discrimination of wellbore effects from reservoir effects.