Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapter

3 – P ressure Transient Analysis (PTA)- p96/743

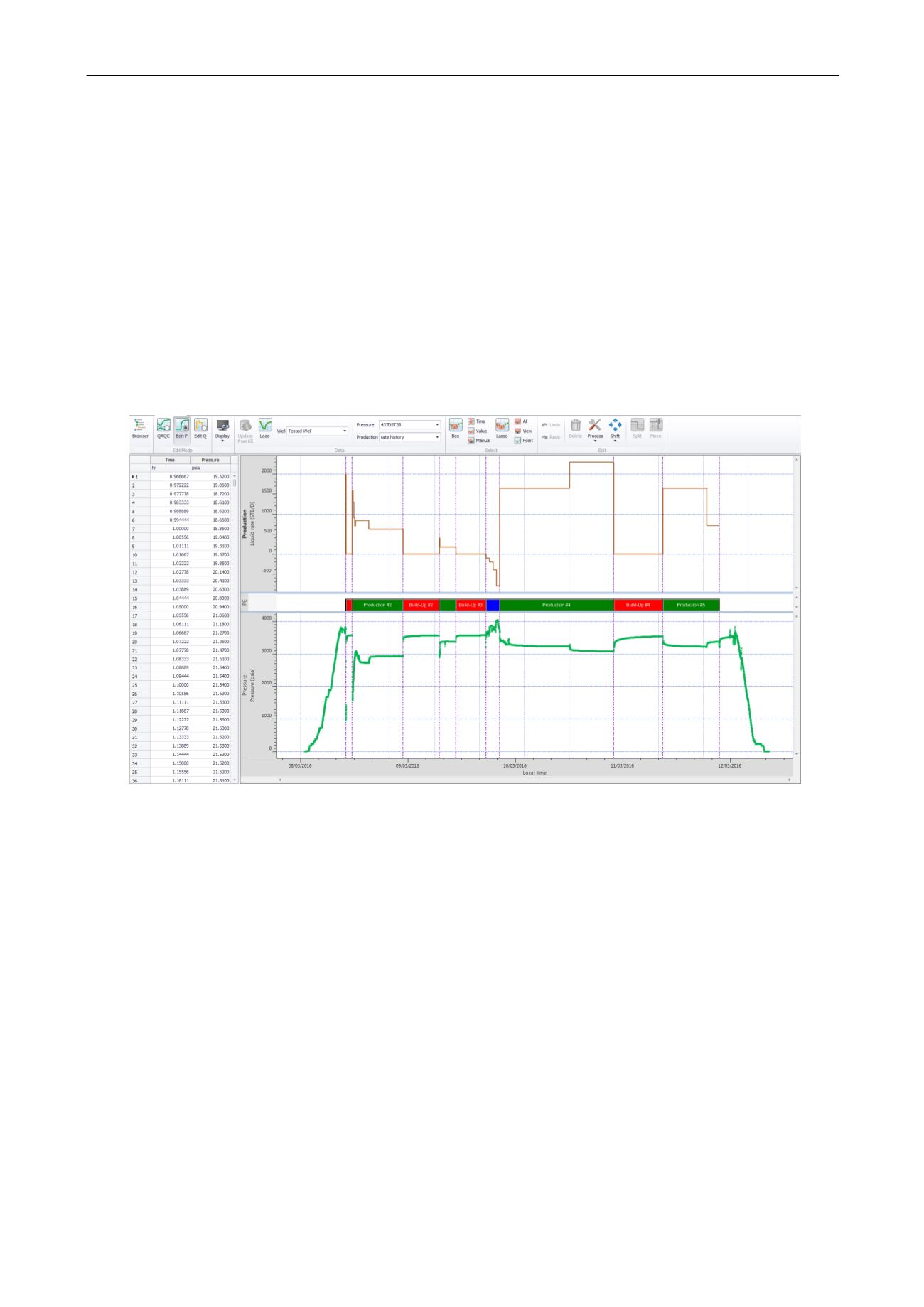

Beyond the usual cleaning of irrelevant data and the correction of load errors, the main

challenge will be to end up with at least one coherent, synchronized set of rate and pressure

data. To get there the engineer may have to perform the following tasks:

Get all data acquired electronically to the same reference time.

If not already loaded, create the rate history graphically by identifying the pressure breaks

and get the rate values from the well test report. Use a facility to automatically identify the

shutin periods and automatically correct the production history from volumes to rates.

Refine the production history, when the time sampling of rate measurements is too crude.

Conversely, if the production history goes into useless details, simplify the rate history to

reduce the CPU time required to run the models.

Fig. 3.E.7 – Editing data:

Pressure and production history adjustment

3.E.5

Extraction and diagnostic

Once the data have been synchronized and validated, the analysis itself will start. The

engineer will focus on one or several gauges, one or several flow periods, and will create the

appropriate diagnostic tools, starting with the loglog and the semilog plots. When several

gauges are used, they will be overlaid. When several production and/or shutin periods are

extracted, they will be rate-normalized, then overlaid. In the case of Saphir, this extraction is

followed by an automatic positioning of a horizontal line for IARF on the Bourdet derivative and

a unit slope line for pure wellbore storage on both pressure and the Bourdet derivative. This

positioning is set by a relatively simple filtration, the main goal being to put these lines in the

same ‘range’ as the data. Surprisingly, this sort of processing works quite well in the case of

simple responses, giving an instantaneous estimate of the wellbore storage and permeability-

thickness product. In case of complex behavior, the software may have selected the wrong

level of the derivative for IARF and or the wrong unit slope for wellbore storage. The

interpretation engineer will then interactively move the two straight lines in order to properly

position these flow regimes.