Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapte

r 3 – P ressure Transient Analysis (PTA) -p103/743

3.F.3

What data, what quality at what cost?

In order to gather the data necessary to meet the test objectives it is required to define the

type of tools that will achieve this. How critical is the accuracy of the downhole measurements

and what are the requirements with respect to surface flow rates? What is the requirement

with respect to frequency of sampling?

As a general rule the higher the sampling rate of a tool, the better it is for pressure transient

analysis. This is certainly the case with respect to downhole pressure and temperature

measurements, but is less critical with the surface flow rate measurements.

The tools must be carefully selected. The downhole gauges must have accuracy adequate for

the expected pressure response. If the differential pressure during a test is expected to be

small (e. g. high permeability and low formation damage) then the accuracy and resolution

becomes an important issue. It is also important to consider if high sampling rate of a tool will

have an adverse effect on its accuracy. How to program a memory gauge or decide to use real

time surface read-out gauge is an issue that needs to be resolved.

If multiphase production is expected in the wellbore or even in the formation then certain

considerations must be addressed. To decrease the wellbore volume, downhole shutin may be

considered to minimize the chances of phase segregation during a buildup and careful

placement of the gauge in the test string is important.

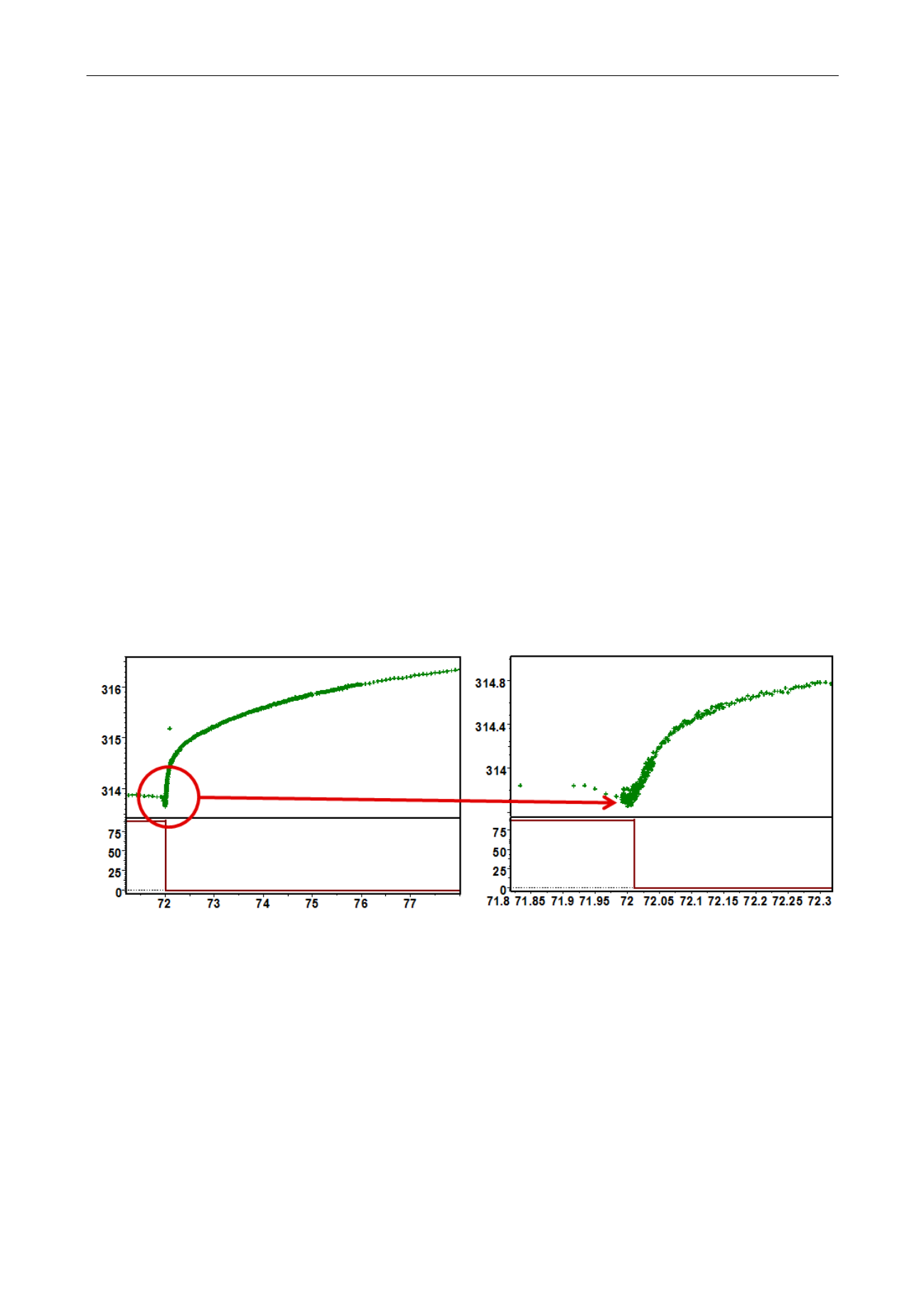

The below figure illustrates the programmed change in pressure acquisition rate just prior to a

buildup. The increase in sampling rate increases the noise.

Fig. 3.F.1 – Increase in acquisition rate

When the diagnostic plot is affected by noise the recognition of the flow regimes becomes

more difficult and the choice of the correct interpretation model becomes ambiguous. See

following illustration.