Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapte

r 3 – P ressure Transient Analysis (PTA) -p107/743

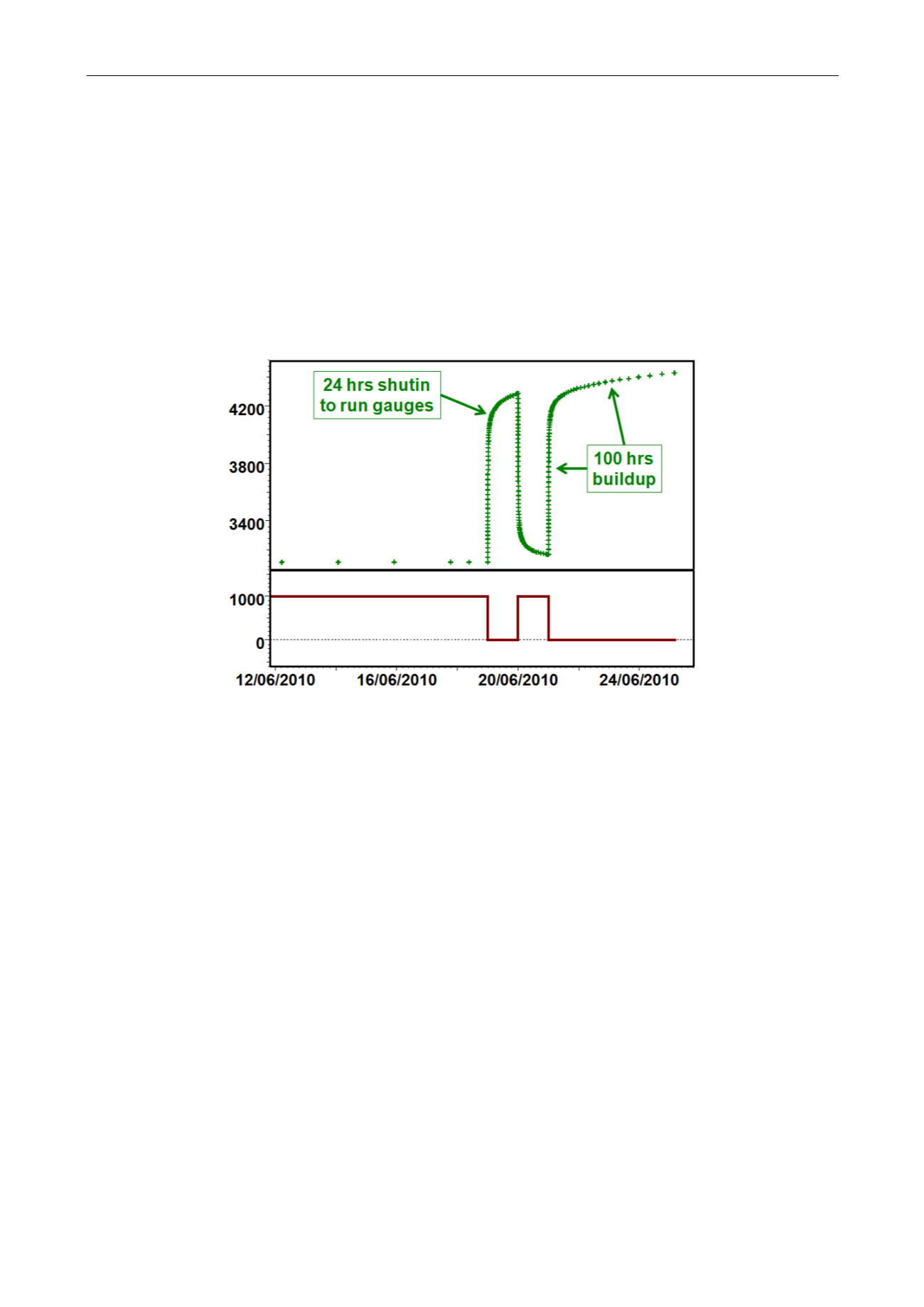

The duration of the shutin that permits for the running and setting of the gauges is set to 24

hours to allow the pressure to stabilize. Then a one single constant production step of 1000

stb/d for 24 hours. This will be followed by a build up of 100 hours. The 100 hours was chosen

as the limit of buildup time. The reason is not necessarily to build up for the actual 100 hours,

but it is a duration that, from most practical viewpoints is the limit of most buildups in

production wells due to the production loss. This allows determining the optimum buildup time

in order to find the permeability, skin and distance to fault. The test design option of the

software was then used to calculate different scenarios and ‘what if’ sensitivities. The

simulated pressure history is shown in the figure below.

Fig. 3.F.7 – Simulated pressure history

The defined production history and the model were used to study the sensitivity to the skin by

running various models and make a comparison. From the figure below it can be seen that

infinite acting radial flow will be reached for skin equal -2 at 7 hours shutin time, and skin of 5

at 14 hours shutin time. The combination of skin above 5 and the fault will mask the radial

flow thus permeability cannot be determined with any confidence. The sealing fault is detected

after about 25 hours shutin time, however the doubling of the slope will only happen after the

end of the 100 hours shutin.

The next figure illustrates that when the storage increases above 0.01 bbl/psi and the skin is

maintained at +10, then radial flow will not be reached and the identification of the fault

becomes ambiguous.