Dynamic Data Analysis – v5.12.01 - © KAPPA 1988-2017

Chapte

r 2 – T heory- p36/743

2.H

Physical meaning of Diffusion

In Pressure Transient Analysis and Rate Transient Analysis, we use the diffusion assumptions

described in the previous section to process measured data, analyze them using models and

finally forecast the well and reservoir response. To do this we have two groups of parameters;

the ‘known’ parameters that we will input and the ‘unknown’ parameters that we calculate.

In the process, we may be tempted to ignore the impact of the known parameters and focus

on unknown parameters. Worse, engineers with improper training may use software defaults

for ‘known’ parameters without considering the impact on the results.

This section is a summarized guide to the influence of all parameters involved in the diffusion

process, whether we input or calculate them.

2.H.1

Reference case

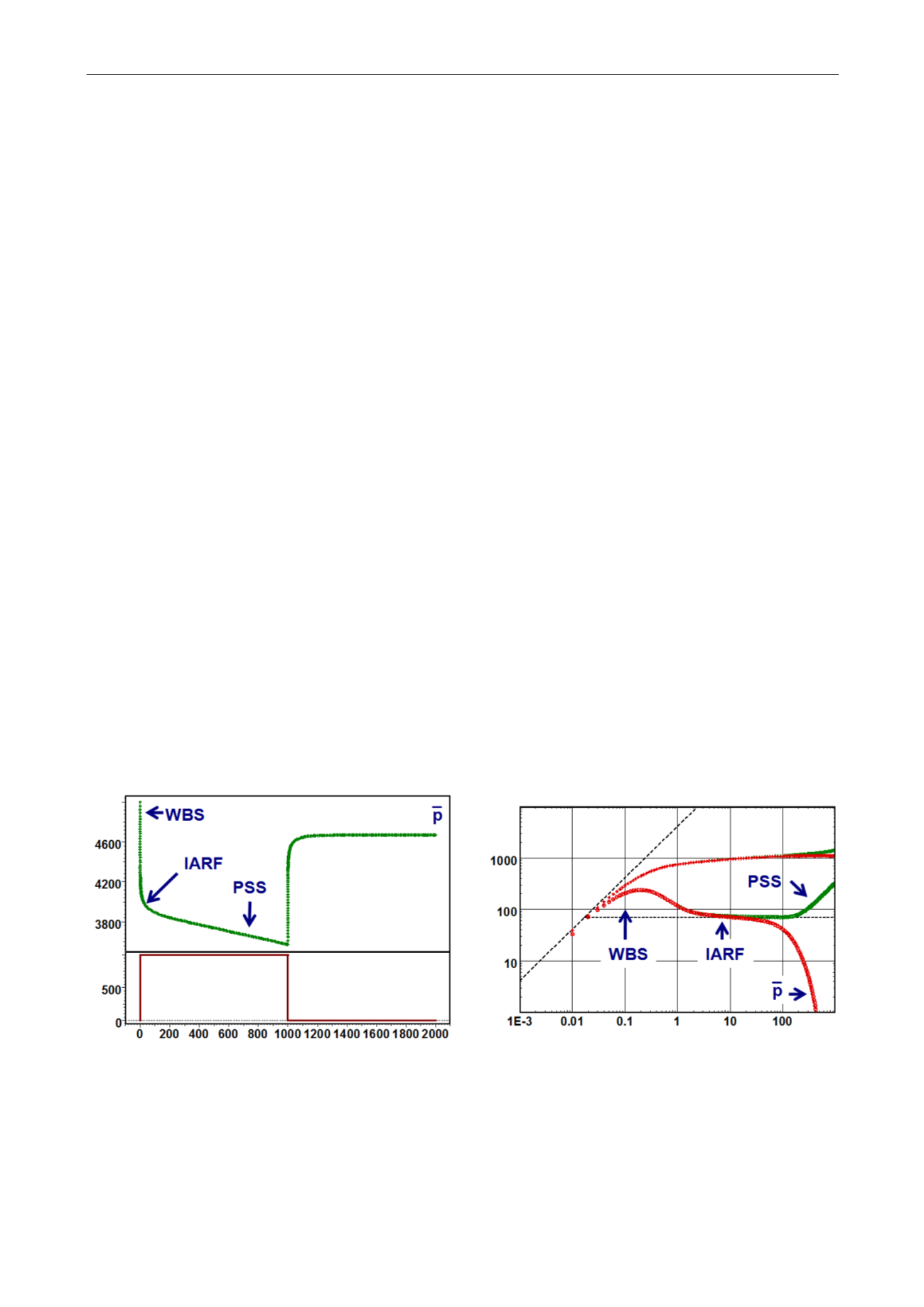

To do this we select a reference case, with arbitrarily long production and shut-in periods.

You may wish to reproduce the whole process in the chapter below by running successive test

designs in Saphir and compare the results using the multi-gauge or multi model option.

We simulate the simplest model that can reproduce the three following flow regimes: Wellbore

Storage and Skin, Infinite Acting Radial Flow and Pseudo-Steady State. We model a vertical

well in a circular homogeneous reservoir centered at the well:

Input parameters: r

w

=0.3 ft; h=100 ft;

=10%; c

t

=1.e-5 psi-1;

=1 cp

Flow rate history: q=1,000 stb/day with B=1; 1,000 hours of flow; 1,000 hours of shut-in

Interpretation ‘results’: p

i

=5,000 psi; C=0.01 bbl/psi; Skin=0; k=10 mD; r

e

=1,500 ft

The result of such design, on both production and buildup, is shown below. The loglog plot

shows both drawdown and buildup periods.

Fig. 2.H.1 – Test Design of the reference case: history and loglog plots